M732i

Trailed Sprayer

- 3,200 L tank volume

- 400 L rinse tank

- 280 L/min pump capacity

- ISOBUS ready

Specifications

Click below for more info

Easy connection to any closed transfer system

Easy connection to any closed transfer system

Fill and rinse the R700i Trailed Sprayers using a closed transfer system. You can plug directly into the container with an adapter that is widely used by crop protection manufacturers.

- Easy connection to any closed transfer system

- Increase safety by avoiding almost any contact with crop protection liquids

Individual nozzle control

Individual nozzle control

Keyfob for remote nozzle diagnoses

Keyfob for remote nozzle diagnoses

Individual nozzle control provides efficient localized crop protection application. Save up to 5 percent in crop protection chemicals – up to 6 EUR per hectare*. The electronically controlled system reaches its ultimate potential together with the pressure recirculation spray functionality.

- Reduce costs by minimizing application skips or overlap

- Protect crops from overapplication of chemicals

- Spray to map makes spot spray possible with individual nozzle control

- Key fob enables remote nozzle diagnoses

*NOTE: Based on a 500-ha wheat farm and assumed costs of 53€/ha for herbicides and 65€/ha for fungicides (5 percent x 118€ = 5,90€/ha).

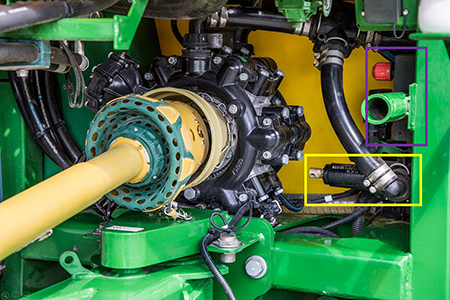

High-pressure circuit regulator (in yellow) and electrically controlled spray pressure (in purple)

High-pressure circuit regulator (in yellow) and electrically controlled spray pressure (in purple)

The pressure regulation system of the M700(i) Series Trailed Sprayers combines a high-pressure circuit to ensure a constant pressure (10 bar [145 psi]) for all auxiliary functions and a low-pressure circuit with an electrically controlled spray pressure for accurate spray application.

Operation station with suction and pressure selection valve

Operation station with suction and pressure selection valve

The centralized operator station on the left-hand side of the sprayer provides superior access to all functions. Clear, allocated symbols reduce the risk of operator mistakes.

For the main functionalities of filling, spraying, agitation. and rinsing, the suction selection valve and pressure selection valve are turned in the same direction.