Specifications

Powerful 19.0-kW (25.5-HP) commercial-grade engine delivers class-leading performance and efficiency

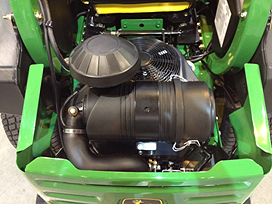

Z930R engine

Z930R engine

The Z930R is powered by an air-cooled, vertical shaft engine:

- 19.0-kW (25.5-HP) petrol engine

Engine features include:

- Overhead valve design

- More horsepower and torque per cubic inch of displacement

- Better fuel efficiency

- Full-pressure lubrication with full-flow filter

- Reduces engine wear by ensuring proper lubrication, even when operating on hillsides or uneven terrain

- Oil filter helps keep oil clean for increased engine life

- V-twin big block design

- Vertical shaft

- Easy-access, dual-element air filter with quick-release latch

- 20-amp alternator

- Fuel pump

- Complies with strict Environmental Protection Agency (EPA) and California Air Resources Board (CARB) emission standards without loss of horsepower or torque

- Aluminum block engines

- Effectively dissipate heat

- Lightweight and strong construction

- Extend engine life due to elimination of debilitating engine temperatures

- Air-cooled engine design

Air cleaner filters out dust that can damage an engine

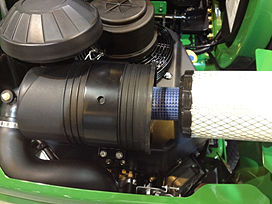

Engine air cleaner

Engine air cleaner

Air cleaner cover removed

Air cleaner cover removed

ZTrak™ Z900 Mowers are equipped with a dual-element, canister-style air filter, easily accessible from the rear of the machine without tools.

- The filtration system pulls clean air from above the engine, in turn filtering out the dust that can damage an engine over time.

- Filters are extremely easy to change when required.

- Pre-cleaner provides more protection against contamination in dusty and dirty applications.

Mow all day on a single tank of fuel with efficient and easy-to-fill fuel tank

Fuel tank and filler neck

Fuel tank and filler neck

Fuel filler neck

Fuel filler neck

The ZTrak Z900 Mowers are equipped with one single-fill, top-draw fuel tank:

- 43.5-L (11.5-US.gal.) capacity enables operators to mow all day without refueling.

- The fuel gauge makes it quick and easy to see how much fuel is in the tank.

- Top draw provides added safety.

- A large fuel-filler neck is angled to make it easy for an operator to complete the fueling process.

Under normal conditions, load, and operation, fuel consumption for the Z900 ZTrak Mowers is 1.5 U.S. gph (5.7 L/hr) to 2.2 U.S. gph (8.3 L/hr), depending on the horsepower and conditions.

54-in. (137-cm) 7-Iron PRO Mower Deck

54-in. (137-cm) 7-Iron PRO Mower Deck

72-in. (183-cm) 7-Iron PRO Mower Deck

72-in. (183-cm) 7-Iron PRO Mower Deck

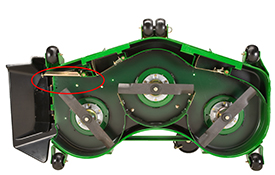

7-Iron PRO mower decks have demonstrated quality, performance, and durability. They deliver a high-quality cut in diverse conditions.

Key features of the 7-Iron PRO mower deck:

- Deck is forged from 7-gauge, 4.6-mm (0.179-in.) steel to minimize the number of welds and provide a smooth underside with fewer sharp corners for reduced material buildup.

- Significantly fewer welds on the deck shell to wear or break – it is forged from a single sheet of steel rather than multiple fabrications. An anti-skid step on the deck provides easy machine mounting.

- Extra reliability and long life with cast-iron blade spindle housings.

- Higher blade tip speed than many competitors – approximately 5,639 m/min (18,500 fpm) for more blade cuts per inch mowed.

- A deep-deck design of 14 cm (5.5 in.) delivers excellent airflow so material can be processed quickly and efficiently.

- The wider and higher discharge opening provides even clipping dispersal for an excellent finished appearance in all conditions.

- Quick-release belt covers do not require tools or the removal of a ring clip; just lift one corner of the cover and rotate it slightly to remove.

- A hole in the deck tab is provided for use of an optional ring clip for extra security, if desired.

- This makes it quick and easy for you to clean out trash that may collect around the spindle sheave.

Mower rectangular leading-edge reinforcement

Mower rectangular leading-edge reinforcement

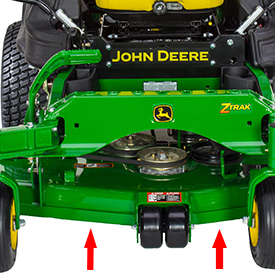

Dual-captured anti-scalp wheel

Dual-captured anti-scalp wheel

- Deck has rectangular leading deck edge reinforcement and the rounded corners of the forged deck help distribute impact stress to reduce the potential of damage when the mower contacts trees, rocks, curbs, and other fixed obstacles.

- Dual-captured front and rear anti-scalp wheels provide deck flotation over even the toughest terrain.

- Three 2.5-cm (1-in.), cold-forged spindles are heat-treated for strength without bulk and are supported by ball bearings, providing reliability and performance; spindle housings are ribbed cast iron providing both excellent strength and heat dissipation.

- The trim edge of the deck is equipped with a bumper that provides great abrasion resistance to protect the machine and the property.

- The front edge is raised above the blade plane to allow even cutting of tall grass and is reinforced with a square bar for durability. The front baffle has been redesigned to better manage airflow and control clippings.

- Three spindle grease fittings are accessible from the top.

- Blade overlap is 40.6 mm (1.6 in.), nearly 20 mm (0.79 in.) greater than previous decks, to reduce striping between blades.

- Quick-change, cutting-height adjustment.

Extra reliability and long life with cast-iron blade spindle housings

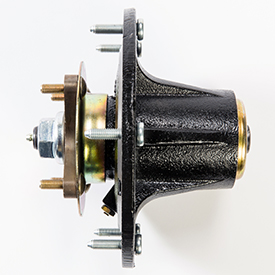

Cast-iron mower spindle

Cast-iron mower spindle

Cast-iron mower spindle

Cast-iron mower spindle

On every commercial mower deck there are three 25-mm (1-in.) spindles that are cold-forged and heat-treated for strength. Spindles are supported by precision ball bearings that provide great performance and reliability.

- Superior impact strength provided by ductile cast-iron material.

- Gusseted design puts reinforcement where it is needed.

- Strength of cast iron protects against damage from blade impacts.

- Easy access grease fittings are mounted at the top of the spindle shafts for convenience.

- Grease pressure-relief valve minimizes seal damage from overfilling with grease and keeps debris from entering housing.

- Chance of deck shell damage is minimized with the 20.3-cm (8-in.) diameter housing and six mounting bolts that distribute loads and impacts.

- Ability to be reliably rebuilt is provided by use of cast iron.

7-Iron PRO mower deck

Mower deck |

Z915E |

Z920M |

Z930M |

Z950M |

Z960M |

Z930R |

Z950R |

Z970R |

48-in. (122-cm) 7Iron PRO side-discharge |

x |

x |

||||||

54-in. (137-cm) 7Iron PRO side-discharge |

x |

x |

x |

x |

||||

60-in. (152-cm) 7Iron PRO side-discharge |

x |

x |

x |

x |

x |

x |

x |

x |

72-in. (183-cm) 7Iron PRO side-discharge |

x |

x |

x |

x |

Mower deck step and trim-edge bumper shown on 54-in. (137-cm) mower

Mower deck step and trim-edge bumper shown on 54-in. (137-cm) mower

The deck step safely aids the operator’s entrance and egress from machine.

Mulch On Demand mower deck

Mulch On Demand mower deck

Mower deck with chute closed

Mower deck with chute closed

The Mulch On Demand mower deck delivers unprecedented levels of productivity and versatility to commercial mower operation. With the ability to switch between side discharge and mulching operation with the flip of a lever as the operator mows, keeping most clippings out of landscaping features and where they are wanted is extremely easy.

Mulch On Demand open

Mulch On Demand open

![Mulch On Demand closed (latch standard on material collection system [MCS] equipped models only)](https://salesmanual.deere.com/sales/salesmanual/images/AU/en/commercial_mowers/features_attachment/ztraks_com/480295_mod_deck_oval_275x175.jpg) Mulch On Demand closed (latch standard on material collection system [MCS] equipped models only)

Mulch On Demand closed (latch standard on material collection system [MCS] equipped models only)

Lever position open (latch standard on MCS-equipped models only)

Lever position open (latch standard on MCS-equipped models only)

Lever position closed

Lever position closed

Key features of the 7-Iron™ PRO Mulch On Demand mower deck:

- Deck can be converted from a wide-open side discharge mode to a fully chambered mulching mode with a single move of a lever.

- NOTE: Mulch On Demand decks are a balance between a side discharge deck and a side discharge deck with a mulching kit.

- Deck is forged from 7-gauge, 4.6-mm (0.179-in.) steel to minimise the number of welds and provide a smooth underside, with fewer sharp corners, for reduced material buildup.

- Significantly fewer welds on the deck shell to wear or break- it is forged from a single sheet of steel rather than multiple fabrications. Anti-skid step on the deck provides for easy machine mounting.

- Mulch On Demand decks are superior to aftermarket chute blockers due to the movable baffles.

- Higher blade tip speed than many competitors – approximately 5,639 m/min (18,500 fpm) for more blade cuts per inch mowed.

- Rounded corners of the forged deck help distribute impact stress to reduce the potential of damage when the mower contacts trees, rocks, curbs, and other fixed obstacles.

- Deep-deck design of 14 cm (5.5 in.) delivers excellent airflow so material can be processed quickly and efficiently.

- Wider and higher discharge opening provides even clipping dispersal for an excellent finished appearance in all conditions.

- Three 2.5 cm (1-in.) cold-forged spindles are heat-treated for strength without bulk and are supported by ball bearings, providing reliability and performance; spindle housings are ribbed cast iron providing both excellent strength and heat dissipation.

- The front edge is raised above the blade plane to allow even cutting of tall grass and reinforced with a square bar for durability. The front baffle has been redesigned to better manage airflow and control clippings.

- Dual-captured anti-scalp wheels provide deck flotation over even the toughest terrain.

- Three greaseable spindle zerks accessible from the top.

- Quick-release belt covers do not require tools or the removal of a ring clip; just lift one corner of the cover and rotate it slightly to remove.

- A hole in the deck tab is provided for use of an optional ring clip for extra security, if desired.

- This makes it quick and easy for you to clean out trash that may collect around the spindle sheave.

- Blade overlap is 40 mm (1.6 in.), nearly 20 mm (0.79 in.) greater than previous decks, to reduce striping between blades.

- Quick-change, cutting-height adjustment.

Extra reliability and long life with cast-iron blade spindle housings

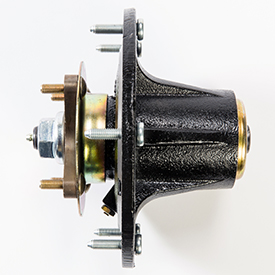

Cast-iron mower spindle

Cast-iron mower spindle

Cast-iron mower spindle

Cast-iron mower spindle

On every commercial mower deck there are three 25-mm (1-in.) spindles that are cold-forged and heat-treated for strength. Spindles are supported by precision ball bearings that provide great performance and reliability.

- Superior impact strength provided by ductile cast-iron material.

- Gusseted design puts reinforcement where it is needed.

- Strength of cast iron protects against damage from blade impacts.

- Easy access grease fittings are mounted at the top of the spindle shafts for convenience.

- Grease pressure-relief valve minimizes seal damage from overfilling with grease and keeps debris from entering housing.

- Chance of deck shell damage is minimized with the 8-in. (20.3-cm) diameter housing and six mounting bolts that distribute loads and impacts.

- Ability to be reliably rebuilt is provided by use of cast iron.

7-Iron PRO Mulch On Demand mower deck

Mower deck |

Z930M |

Z950M |

Z960M |

Z930R |

Z950R |

54-in. (137-cm) 7Iron PRO Mulch On Demand |

|

x |

|

x |

|

60-in. (152-cm) 7Iron PRO Mulch On Demand |

x |

x |

x |

|

x |

ComfortGlide fore/aft suspension

ComfortGlide fore/aft suspension control lever

ComfortGlide fore/aft suspension control lever

The seat has the ComfortGlide fore/aft suspension system that gives superior ride comfort over uneven areas:

- Seat can travel up to 50.8 mm (2 in.) fore and aft to absorb bumps for a significant enhancement to ride comfort.

- Control lever provides the ability to easily lock out fore/aft suspension movement if desired.

- One lever has three functions:

- Slide seat forward and back 10.2 cm (3 in.) to allow the operator the ability to choose the leg room needed

- Activate ComfortGlide fore/aft seat suspension

- Lock out ComfortGlide fore/aft seat suspension

Fully adjustable suspension seat with armrests

Fully adjustable, mechanical suspension-seat

Fully adjustable, mechanical suspension-seat

Suspension seat control

Suspension seat control

A fully adjustable suspension seat with armrests is standard on R Series:

- Adjustable back angle is provided for individual operator comfort.

- Adjustable lumbar support helps to suit the needs of the operator.

- A suspension seat control dial gives easy adjustment for operator weight and ride comfort.

- A convenient seat latch provides ease of lifting the seat.

Designed for operator comfort

Operator station

Operator station

Two-lever hydrostatic control provides the following:

- The operator can select the ground speed and direction control simply by moving levers forward or reverse.

- Positive neutral lock position for levers provides added safety.

- Brake & Go operator-presence system returns levers to the neutral position when the brake pedal is actively engaged.

- Starting the machines is as easy as starting a car. It no longer matters if the control levers are extended out or pulled in, as long as the parking brake is engaged. Just turn the key and go.

- Wide-bend, large-diameter steering levers swing out easily for entry and exit from the operator platform.

Foot pegs

Foot pegs available as standard on R-spec Z900’s

Foot pegs available as standard on R-spec Z900’s

Foot pegs help in providing the operator with a comfortable foot placement:

- Location and angle of foot pegs can be adjusted for individual operator comfort.

Foot platform isolators

Foot platform isolators

Foot platform isolators

Foot platform isolators provide the operator with added comfort:

- Vibration to the legs and feet is reduced.

Brake & Go starting system

Parking brake pedal (Z900R Series)

Parking brake pedal (Z900R Series)

Parking brake lever (Z900 E and M Series)

Parking brake lever (Z900 E and M Series)

The Brake & Go starting system is a John Deere exclusive. This feature makes the starting process on all ZTrak™ mowers easier, while also making it possible to remove two interlock switches from the machine.

The Brake & Go starting procedure helps a novice operator look and feel like a professional. To start the machine, the parking brake must be engaged. It does not matter whether the power take-off (PTO) switch is on or off, nor does it matter if the control levers are pulled in or in the out position.

As long as the parking brake is engaged, the machine will start. When the parking brake is applied, the control levers cannot be moved to the forward or reverse positions.

Adjustable levers

Adjustable levers

Adjustable levers

The motion control levers have two height positions and can also be adjusted forward or rearward within the slotted holes. The levers should be adjusted so the operator can achieve a full range of control operation comfortably.

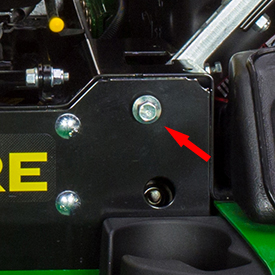

Tracking adjustment

Tracking adjustment

Tracking adjustment

The easy-to-turn (from-the-seat) tracking adjustment allows operators to keep their mowers straight and able to produce professional striping results.

Onboard storage and cup holder

Onboard storage

Onboard storage

Cup holder

Cup holder

Several storage areas are provided on the ZTrak machines. A convenient cup holder is also available.

Right-hand control panel

Right-hand control panel

Right-hand control panel

Right-hand control panel

Right-hand control panel

The controls are grouped together on the right console, providing one central location for key switch, throttle, PTO engagement, height-of-cut, diagnostics, and hour meter:

- Rocker-type PTO switch

- Height-of-cut knob with transport lock

- Key switch

- Hour meter

- Throttle

- Separate choke control

- Easy choke operation yields less fouling of plugs

- No choke required for the electronic fuel injection (EFI) models

Easy-to-operate height-of-cut adjustment enables on-the-go changes

Mower deck height adjustment knob

Mower deck height adjustment knob

An easy-to-use cutting-height lift system allows the operator to adjust the mower deck height with no tools and minimal effort. The easy-to-grip knob allows operators to dial in the desired height of cut (HOC).

Cutting height can be adjusted from approximately 2.5 cm to 14 cm (1 in. to 5.5 in.). Each increment on the knob adjusts the HOC approximately 0.64 cm (0.25 in.). The deck can also be raised and locked in a transport position to provide maximum ground clearance when moving the machine from one area to another.

The transport lock function allows the deck to be returned to the previous HOC after being in the transport position:

- Use the foot-lift pedal to lift the deck and engage the transport lock.

- Rotate the knob to adjust from 2.5 cm to 14 cm (1 in. to 5.5 in.) in 6.4 mm (0.25-in.) increments.

This design increases productivity by allowing operators to change the cutting height without having to leave the seat.