Specifications

W260R cutting a center windrow discharge in field

W260R cutting a center windrow discharge in field

Increase productivity by combining up to three windrows at time of cut, with the new John Deere Merger Attachment. It provides a versatile solution with the option of creating a center windrow discharge or a side windrow discharge. This solution helps enable the operator to get the windrow width and volume they desire. By raising the merger the operator can discharge the crop under the traction unit, creating their desired center windrow shape.

W260M side discharge with merger attachment in field

W260M side discharge with merger attachment in field

In order to side windrow discharge, the merger is engaged by lowering the merger table. The Self-Propelled Windrower will detect when the merger is installed, which will automatically intergrate the merger lift state identifier, merger drive status, master merger switch, and the belt slip indicator into the display. The merger attachment is capable of moving crop either on top of or next to another windrow, so when the merger attachment is engaged, the operator can combine up to three windrows together.

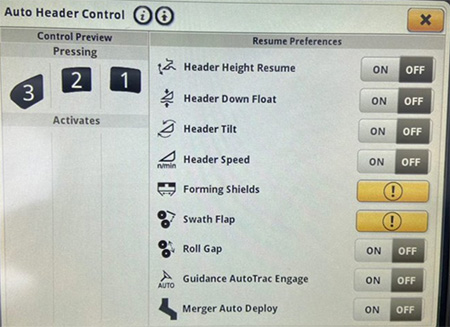

Display page to pre-set hyrdo-handle buttons

Display page to pre-set hyrdo-handle buttons

In cab hydro-handle

In cab hydro-handle

Ease Of Use

The merger offers integrated functions, including the lift state identifier, merger drive status, master merger switch, and the belt slip indicator. It detects merger and head engagement and notifies the operator if the merger is in the down and off position. Certain features are automatically pre-set by default when the merger master switch is turned to on, it automatically integrates the preset 1/2/3 commands with the automation buttons. When the merger master switch is on, button one raises the head and merger to be used at the end of a row, button two lowers the head and merger while engaging the merger, and button three prepares the head for a center windrow discharge. Conversely, if the merger master switch is off, these commands will not be displayed. The merger presets can be toggled On/Off using the automation button run page.

Other features like TouchSet™ and AutoTrac™ guidance, can also be controlled with the press of a button from the intergrated in cab hydro-handle. TouchSet allows for platform features like windrow width formation, swath flap, forming shields, and roll gap adjustments to be controlled from the comfort of the cab. The AutoTrac guidance system enables precise steering and path accuracy, minimizing overlaps and skips during operation, resulting in improved efficiency and field coverage. These features contribute to the overall ride experience and mowing performance.

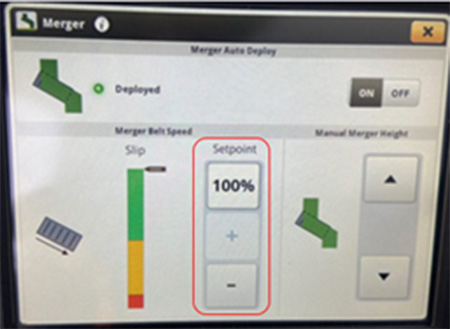

Display page for setting belt speed

Display page for setting belt speed

Adjustability

On the John Deere Merger Attachment, the options for adjusting merger to crop conditions include modifying the belt speed and belt angle.

Belt speed is adjustable to include a variety of throw distances that include options for next-to or on-top-of discharge, enabling the operator to get the windrow shape they desire. To make adjustments the operator can increase or decrease belt speed by increasing or decreasing the set point on the merger display screen or can control the belt speed by using the hydro-handle rear scroller. The merger height can also be adjusted by using the height adjustment buttons found on the merger run page.

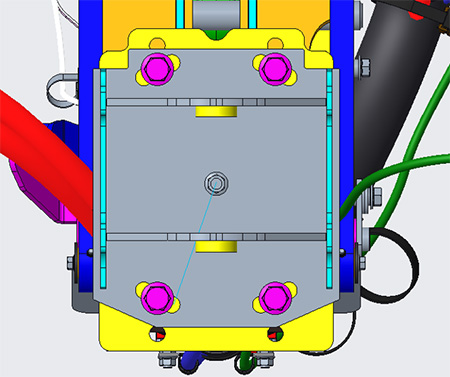

Angle adjustment bolts on lift system

Angle adjustment bolts on lift system

The merger angle is adjustable by adjusting the four bolts on the lift system to the desired angle and by adjusting to the desired speed. Altering the merger angle affects the trajectory of the crop. These adjustments empower operators to attain their preferred windrow shape. Additionally, no adjustments are required for belt tracking because the merger features self-aligning belt tracking and is equipped with a single-point belt tension.

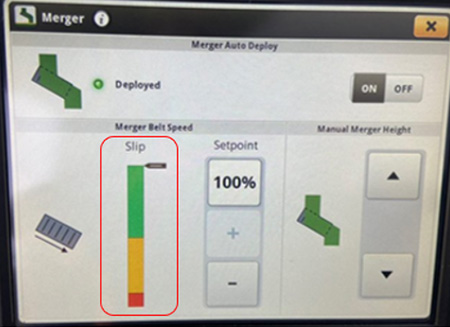

Industry exclusive belt slip notification display page

Industry exclusive belt slip notification display page

The merger attachment comes with an industry exclusive belt slip notification feature,, which protects merger components and impacts job quality. which detects any belt slippage, indicating something is wrong. The belt slip indicator shows the current status of the belt by having the indicator hover over the colors green, yellow, or red, which helps the operator understand the conditions of the single belt while cutting. This improves decision-making and drives overall operational efficiency.

| Green | Merger is running in healthy conditions. |

| Yellow | Will warn the operator to check the system, which could indicate plugging, belt tension, hydraulic leak, or crop build up. |

| Red | Means extreme slip and will shut off merger belt and head to protect the system. |

Compatability

The John Deere merger attachment is compatible with the R500 roll conditioner platform only, as well as the W235M, W235R, W260M, and W260R Self-Propelled Windrowers.

See compatability table below:

John Deere Merger Attachment (Compatible Windrowers & Platform)

|

|

W235M |

R500 Roll Conditioners ONLY

|

W235R |

|

W260M |

|

W260R |

|

*Merger attachment is NOT recommended with the R400 Platform and R500 Impeller Head *Merger attachment is NOT recommended with the W200M Windrower

|

|

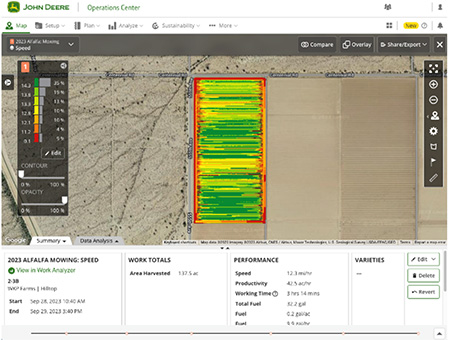

Field Analyzer

Field Analyzer

Work Analyzer

Work Analyzer

NOTE: Mowing and Swathing used interchangeably.

Mowing Documentation in John Deere Operations Center™ allows the following information to be available anytime, anywhere.

- Utilize the cut date history to identify fields that need cut next by reviewing previous cut dates and scheduling the next required cuts and then quickly send the information to operator’s display via a Work Planner file.

- Assess dry down times using Mowing Documentation in conjunction with Bale Documentation through the John Deere Operations Center by reviewing the days between mowing and bailing.

- Look for efficiency opportunities by machine or operator, such as speed, productivity, fuel rate per area, and fuel rate per hour to understand field performance via coverage maps and seasonal performance in Work Analyzer.

- JDLink™ provides seamless transfer of machine and agronomic data between equipment and Operations Center, which improves monitoring, planning, logistics and ease of analysis.

M-spec cab

M-spec windrower cab interior

M-spec windrower cab interior

M-spec windrower cab exterior

M-spec windrower cab exterior

The W200M, W235M, and W260M Self-Propelled Windrowers come with a cab that offers a comfortable and quiet working environment with plenty of visibility, storage, and features.

- JDLink™ system enabled

- AutoTrac™ assisted steering system ready

- Rear window tint

- Automatic temperature control – R-spec only

- Two halogen rear worklights

- Great visibility

- Operator’s seat with mechanical suspension

- Folding instructor seat

- AM/FM radio with Bluetooth® wireless functionality

- Tilt steering column

- Cornerpost display

- Two 12-V power outlets

- Sun visor

- Halogen lights

- Ergonomic multi-function lever

- 4200 CommandCenter™ Display

R-spec cab

R-spec windrower cab interior

R-spec windrower cab interior

R-spec windrower cab exterior

R-spec windrower cab exterior

The R-spec cab comes in three different trim levels:

- Select

- Premium with air suspension seat

- Premium with active seat

|

Select |

Premium with air suspension |

Premium with active suspension |

|

Comfort and Convenience |

Seat |

|

|

|

Infotainment |

|

|

|

|

Interior upholstery |

Upholstery without right-hand storage |

Upholstery with right-hand storage |

Upholstery with right-hand storage |

|

Exterior styling |

Without exterior styling panels |

With exterior styling panels |

With exterior styling panels |

|

Visibility |

Lighting |

Halogen |

LED |

LED |

Mirrors |

Manual |

Electric heated |

Electric heated |

|

Sunshades |

Front |

Front/rear |

Front/rear |

|

Wipers |

Front |

Front |

Front |

|

Seat suspension |

Air (passive) |

Yes |

Yes |

No |

Active suspension |

No |

No |

Yes |

|

Precision Ag Technology |

Integrated StarFire™ receiver |

Integrated StarFire ready |

With Integrated StarFire |

With Integrated StarFire |

Extended display |

No |

No |

No |

|

Bluetooth is a trademark of Bluetooth SIG, Inc.

CommandARM console in the W200M Windrowers

CommandARM console in the W200M Windrowers

CommandARM console in the W200R Windrowers

CommandARM console in the W200R Windrowers

The CommandARM console provides the operator with unmatched control of the windrower and platform. Controls are designed and positioned to enhance ergonomics and are easy to locate and use. Operators will appreciate the look and feel of the control console in the windrowers, which are similar to the design used in John Deere tractors and combines.

Adjustment of the CommandARM console meets the needs of every operator. It adjusts at an angle, fore/aft, and up and down for precise operator comfort.

The CommandARM console provides access to the most frequently used windrower controls:

- Field/road speed range

- Float adjust

- Platform speed adjustments

- Throttle – low idle, variable idle, and high idle

- Platform engage/disengage

- Windrower merger speed, raise, and lower (if equipped)

- Road hazard engage/disengage

- Gen 4 CommandCenter™ display navigation

- Display menu shortcut buttons

- Climate control switches

- Worklight switches

- Beacon light switches

Multi-function lever

The controls vital to the operation of the W200 Series Windrowers are conveniently located on the multi-function lever. The ergonomic multi-function lever gives the operator fingertip control of the following functions:

- Platform float suspension adjustment

- Windrower merger position (if equipped)

- Platform presets (to raise, lower, and engage AutoTrac™ system)

- Increase/decrease cutterbar or draper speed

- Platform raise/lower

- Platform tilt

The multi-function lever is also associated with the following functions:

- Forward/reverse ground speed

- Automatically disengages the park brake when moved from the park position with the engine running

- The park brake is automatically engaged when placed in park.

- With platform enabled and on rotary traction units only, automatically raises the platform when moved from forward to reverse position

- This function prevents wrapping cut crop into condition rolls.