9700

Self-Propelled Forage Harvester

- 566 kW (759 hp), 24 L Liebherr V12 engine

- Driveline designed to deliver optimal crop flow when the engine is operating in its efficiency sweet spot

- The ProStream crop flow designed with extra heavy-duty components for high horsepower and more throughput than ever before

Specifications

Click below for more info

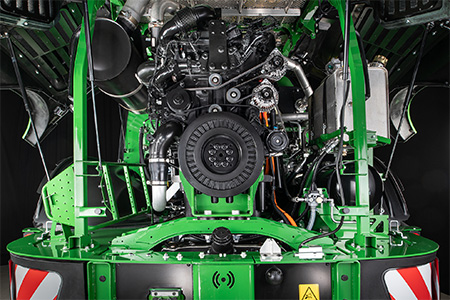

John Deere JD18X engine

John Deere JD18X engine

The John Deere JD18X engine with 18L (1098-cu in.) displacement delivers unmatched performance and characteristics. The unique engine characteristics and efficiency brings the John Deere self-propelled forage harvesters (SPFH) into another performance league in the 514- to 588-kW (690.4- to 789-hp) power class. With the JD18X engine comes unique features and highest comfort on the 9500, 9600 and 9700 SPFH models.

- Perfect engine characteristics for SPFH application

- Diesel only engine – no diesel exhaust fluid (DEF)/AdBlue® with Final Tier 4 (FT4)/Stage V (EU) emission regulation

- HarvestMotion Plus

- Long engine oil service interval (750 hours)

The JD18X engine was awarded “Diesel of the year 2021,” confirming the performance and diesel-only concept. Click here for more information.

Diesel of the year award

Diesel of the year award

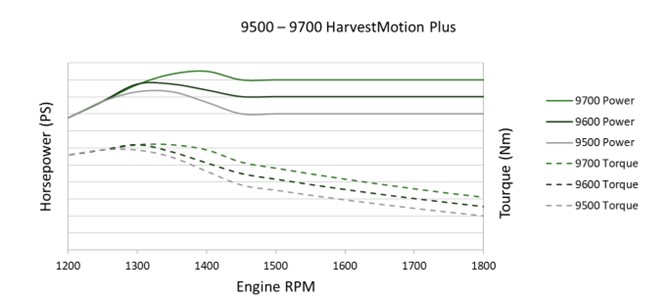

The unbeatable performance of the JD18X engine together with the HarvesMotion Plus concept achieves unique power and torque rise in the 514- to 588-kW (690.4- to 789-hp) power class.

Power and torque rise through engine rpm on the 9500-9700 SPFH

Power and torque rise through engine rpm on the 9500-9700 SPFH

The unique engine characteristics with constant, strong power and torque rise at low rpm provides a highly efficient forage harvester and comfortable driving in every situation.

| Model | Rated power | Maximum power with HarvestMotion Plus | Power growth at lower rpm | |

| 9500 | 515 kW (690.4 hp) | 563 kW, 755 hp | 48 kW, 64.4 hp | 9,3 percent |

| 9600 | 552 kW (740.2 hp) | 579 kW, 776.5 hp | 27 kW, 36.2 hp | 4,9 percent |

| 9700 | 589 kW (789 hp) | 607 kW, 814 hp | 18 kW, 24.1 hp | 3,1 percent |

AdBlue is a trademark of VDA Verband der Automobilindustrie e.V.

HarvestMotion Plus – A state-of-the-art engine with ideal performance characteristics and low specific fuel consumption perfectly aligns and synchronizes with a superior crop flow. This is the John Deere HarvestMotionTM concept. The “Plus” stands for unique torque rise and more power at low engine rpm – an experience of pure performance and efficiency without any compromise. Additionally, there is no diesel exhaust fluid (DEF) required.

The HarvestMotion Plus advantage:

- 13 percent less fluid consumption (diesel plus DEF)

- 48-kW (64.4-hp, varies by model) extra power at low engine rpm to easily digest peak loads

- Simple is strong – reliable harvest capacity

John Deere 9000 Series with JD18X engine

John Deere 9000 Series with JD18X engine

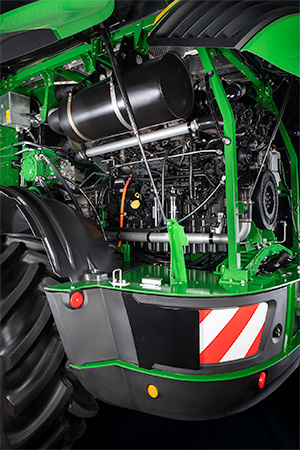

Leading efficiency

With a maximum engine speed of 1800 rpm, the engine is always operated in its sweet spot. Lower rpm means lower specific fuel consumption. Less fuel consumption means less costs and, in the end, more money in your pocket. HarvestMotion enables up to 13 percent less total fluid consumption, which equals up to 105€ per day of grass harvest and 119€ per day of corn harvest*.

*NOTE: Based in internal benchmark data from 2020: JD18X John Deere engine with HarvestMotion Plus versus replaced model with 4 percent less diesel, no DEF (AdBlue®), and 10 hours of chopping per day.

Powerful heartbeat

Less engine rpm, more power, and a unique torque rise – this is what HarvestMotion Plus delivers. The JD18X John Deere engine has been tailored to the needs of an agricultural harvesting machine. Operators will feel its strength and owners will profit off its harvesting capacity. The JD18X engine in the 9000 Series Self-Propelled Forage Harvester (SPFH) with the HarvestMotion Plus concept is a winning combination.

- The 9500 SPFH delivers 23 percent more throughput than the previous 9600 SPFH with 13.5L (824-cu in.) engine.

- Get the same high productivity level on the 9500, 9600 and 9700 SPFH as the Liebherr® V12 engine provides on the other 9000 Series models (throughput/installed engine power).

Reliability through simplicity

Reliable power delivered by modern, robust engine technology ensures harvesting capacity. The JD18X engine delivers exceptional performance without needing a complex aftertreatment system. This means unique simplicity in this power class.

AdBlue is a trademark of VDA Verband der Automobilindustrie e.V. Liebherr is a trademark of Liebherr-International AG.

Overview

John Deere self-propelled forage harvesters (SPFH) set new standards in kernel processing performance. Proven in independent tests during corn harvest in 2016 and 2017, John Deere kernel processors (KP) deliver smashed kernels and highly processed plants that growers expect. With two different models, the John Deere Premium KP™ kernel processor and the John Deere XStream KP™ kernel processor, all different needs will be satisfied.

Additional details

All John Deere SPFH can be operated with or without a kernel processing unit in position. When not in use, a crop transition chute (or grass chute) swings into position with a few turns of a crank. The crop transition chute comes standard on all harvesters.

The SPFH feature the AutoLube central greasing harness; the respective central greasing equipment is available on the Premium KP kernel processor. The XStream KP kernel processor features automatic pressurised oil lubrication.

The John Deere Premium KP is available for 9500 through 9800 models, and the John Deere XStream KP is available for all 9000 Series models. The 9900 model can only be equipped with an XStream KP.

John Deere Premium KP

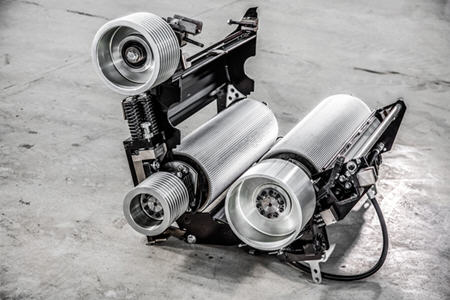

John Deere Premium KP kernel processor

John Deere Premium KP kernel processor

On the 9000 Series, the proven John Deere Premium KP can be installed on the 9500 through 9800 models. With their highly intense processing, they deliver excellent forage quality at any length of cut.

The main features of the Premium KP are:

- 240-mm (9.45-in.) roll diameter for different crops (maize and whole crop)

- 32 percent speed differential; option of 40 percent speed differential

- Standard KP housing with grease lubrication in base

- Electric KP gap adjustment from the cab as option

The following rolls are available for the Premium KP:

- Standard sawtooth (118/118 teeth)

- Dura Line™ sawtooth (118/118 teeth)

- Whole crop sawtooth (178/178 teeth)

With the option of Dura Line rolls, a longer lifetime and less wear can be reached, resulting in lower cost of operation.

For easy and uncomplicated mounting and dismounting of the KP, a crane with electric winch can be installed as an option.

Mounting and dismounting the KP with the optional crane and winch

Mounting and dismounting the KP with the optional crane and winch

The following diagram shows the complete John Deere Premium KP offering with all possible combinations.

|

Sawtooth (118/118 teeth) – code 3734 |

|

John Deere Premium KP with:

|

Dura Line sawtooth (118/118 teeth) – code 3738 |

|

Whole crop sawtooth (178/178 teeth) – code 3743 |

The following additional options are also available for the Premium KP.

Crane for KP removal complete with electrical winch (code 8380)

Crane for KP removal complete with electrical winch (code 8380)

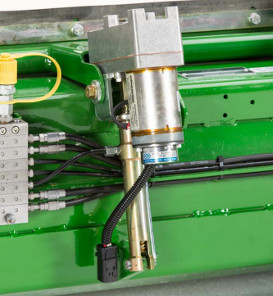

Hydraulic KP belt tensioner (code 8381)

Hydraulic KP belt tensioner (code 8381)

Electrical KP gap adjustment (code 8376)

Electrical KP gap adjustment (code 8376)

40 percent speed differential (code 8378)

40 percent speed differential (code 8378)

Complete whole crop KP as bundle (code 9379)

Complete whole crop KP as bundle (code 9379)

John Deere XStream KP

John Deere XStream KP kernel processor

John Deere XStream KP kernel processor

The John Deere XStream KP is the heavy-duty solution made for high throughput and high-horsepower machines and stands for extreme processing at any length of cut in any crop and any conditions.

The XStream KP rolls are manufactured and delivered by Scherer Inc., located in South Dakota, United States. The kernel processor is supplied ex-factory by Scherer Inc. and fits on all 9000 Series models. As Scherer Inc. has a strong focus on dairy forage production and is the leading company in KP roll designs and manufacturing since 1999, a strong statement is set regarding kernel processing and forage quality.

More information about Scherer Inc. can be found on their website: http://www.schererinc.com/

The main features of the XStream KP are:

- 250-mm (9.8-in.) roll diameter

- 50 percent speed differential

- Heavy-duty housing with KP roll quick-exchange system

- Pressurised oil lubrication of bearings

- Bearing temperature monitoring system (option)

The following rolls are available for the XStream KP:

- Dura Line sawtooth (110/145 teeth)

- Dura Line XCut (110/145 teeth)

- Dura Line Whole Crop XCut (145/165 teeth) – only available for 9000 Series

All XStream KP options for 9000 series are available with 10- or 11-inch rolls.

In comparison to the Dura Line sawtooth rolls, the Dura Line XCut rolls have a spiral groove sawtooth profile that delivers excellent processing, especially at long lengths of cut. The spiral groove design delivers highly processed plants and smashed kernels.

For easy and uncomplicated mounting and dismounting of the KP, a crane with electric winch can be installed as an option.

Mounting and dismounting the KP with the optional crane and winch

Mounting and dismounting the KP with the optional crane and winch

The following diagram shows the complete John Deere XStream KP offering with all possible combinations

|

Dura Line sawtooth (110/145 teeth) – code 3750 |

|

Requires:

|

Dura Line XCut sawtooth with spiral groove (110/145 teeth) – code 3751 |

|

Dura Line XCut sawtooth with spiral groove for whole crop (145/165 teeth) – code 3752 |

The following additional options are also available for the XStream KP.

Temperature monitoring (code 838A)

Temperature monitoring (code 838A)

Crane for KP removal complete with electrical winch (code 8380)

Crane for KP removal complete with electrical winch (code 8380)

Overview

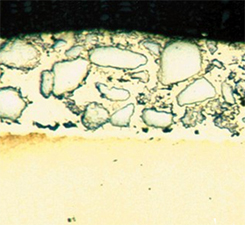

Due to increased machine usage (chopping more tons per hour), standard high-quality steel parts need to be replaced more frequently. Since 2010, John Deere has been meeting the challenge and exceeding expectations with Dura Line wear parts.

Dura Line components were developed by John Deere and are installed in high wear spots on the self-propelled forage harvesters (SPFH), mainly in the crop flow. The technology is normally used for heavy-duty environments such as mining and machine tooling. It is the highest material quality in the industry that is installed on an SPFH.

Benefits

- The coating is extremely wear resistant with an extraordinarily smooth surface due to the special heat treatment and a proprietary tungsten carbide composition.

- Dura Line provides a permanent fast-chopping process with low crop friction on the components while fuel consumption remains low.

- Tests show that when chopping in the same crop conditions and chopping the same tonnage, Dura Line parts last four times as long as, or longer than, standard parts. Time and money associated with replacing parts are significantly reduced.

Dura Line coating

Dura Line coating

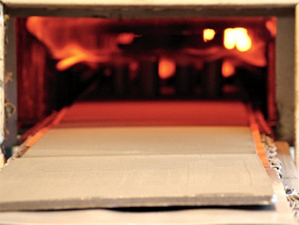

Dura Line processing

Dura Line processing

Additional details

Dura Line guarantee

The Dura Line guarantee provides a specified number of engine hours or time of usage (whichever comes first) for the different Dura Line liners. The Dura Line guarantee was first introduced in 2017 and is valid for all 8000 and 9000 Series SPFH models. Dura Line liners damaged from foreign material or misuse are excluded. Only parts that are completely worn are replaced.

For more information about the Dura Line guarantee, contact the local sales organisation.

Dura Line packages

The John Deere Dura Line crop flow liners come in three packages. Depending on the individual harvesting requirements, there is a perfect package for every need.

- Basic: Perfect solution for machines mainly harvesting corn

- Premium: Ideal for abrasive conditions (particularly grass)

- Ultimate: Perfect choice for toughest conditions, providing full crop flow coverage

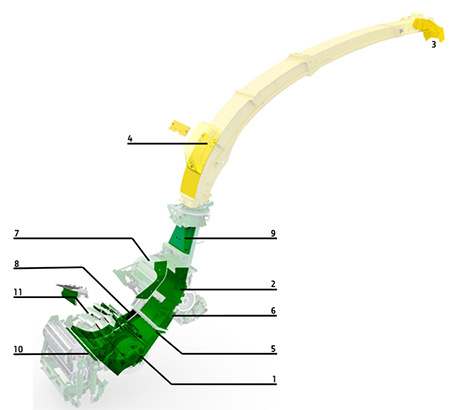

Dura Line wear parts

Dura Line wear parts

| # | Dura Line component | Basic | Premium | Ultimate |

| 1 | Spiral band | √ | √ | √ |

| 2 | Accelerator band | √ | √ | √ |

| 3 | Spout flap | √ | √ | √ |

| 4 | Spout wear liners | √ | √ | |

| 5 | Front chute base liner | √ | √ | |

| 6 | Grass chute base liner | √ | ||

| 7 | Accelerator side wall liners | √ | ||

| 8 | Front chute side liners | √ | ||

| 9 | Transition front liners | √ | ||

| 10 | Dura Line smooth roll scraper | √ | √ | √ |

| 11 | Dura Line knife holder | √ |

NOTE: 3000 engine hours or 5 year guarantee.