Specifications

24-row 1775NT Planter equipped with ExactRate system

24-row 1775NT Planter equipped with ExactRate system

The ExactRate fluid transfer system pairs planters seamlessly with the ExactRate tractor tanks. It provides an easy connection point to allow transfer from the ExactRate tractor tanks back to the planter tank. This enables up 6056 L (1600 gal.)* of combined capacity between the tractor and planter tanks.

- Factory installed

- Designed and tested by John Deere to ensure the lines won’t pinch when folding

- Easily attaches to the ExactRate tractor tanks

ExactRate is available on the following models: 1775NT, 1795, DB44, DB60, and DB66.

*NOTE: 6056 L (1600 gal.) assumes a 2271-L (600-gal.) tank on a 24-Row 1775NT Planter as well as the 3785-L (1000-gal.) capacity on the 8RX Tractor.

24-row 1775NT Planter equipped with ExactRate fluid transfer system

24-row 1775NT Planter equipped with ExactRate fluid transfer system

Liquid tank mounted on a 24-row 1775NT Planter

Liquid tank mounted on a 24-row 1775NT Planter

John Deere factory-installed liquid tanks offer a convenient way to carry fluid on the planter frame. Styling cues match the CCS™ system tanks, and all brackets and mountings are 100 percent factory installed.

- Factory installed

- Up to 2271 L (600 gal.) of fluid capacity

- Clear sight tube to check fluid level

- Air bleed and overflow protection

Liquid Tank mounted to a 24-row 1775NT Planter

Liquid Tank mounted to a 24-row 1775NT Planter

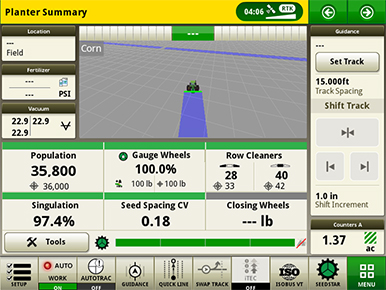

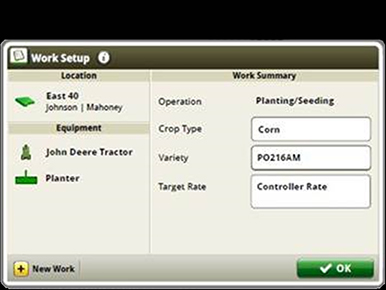

Have you wanted to view more than one planter chart at once? SeedStar 4HP gives you multiple views and configurations in one simple overview page to fit your preferences. You can complete the simplified setup from the Work Setup page instead of having multiple applications to open.

SeedStar 4HP is designed to optimize the in-cab monitoring experience exclusively on the Gen 4 4600 CommandCenter™ display or 4640 Universal Display for growers with ExactEmerge™ planters and MaxEmerge™ 5e planters. With SeedStar 4HP, operators will easily see key planter information with customizable run pages, zoom functionality, and simultaneous graph and performance measurements. SeedStar 4HP is included in base on all model year 2018 ExactEmerge and MaxEmerge 5e planters.

Features overview:

- View multiple planters’ at-a-glance bar charts simultaneously

- Three default planter run pages show key planter functions in easy-to-view layouts

- Highly configurable run pages allow SeedStar modules to be customizable

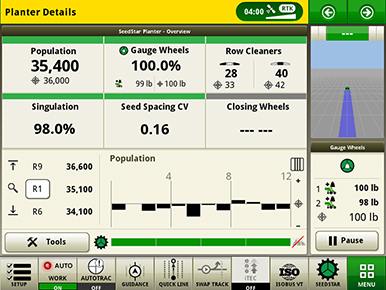

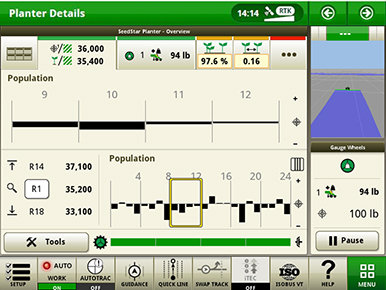

- Zoom feature allows quick row-by-row detailed information

- View dual bar graphs to see multiple planter details at one time

- SeedStar application to make adjustments to planter functions

- Simplified setup through the work set-up page

- Advanced rates allow up to six different rates across 48 rows

- The SeedStar 4HP monitoring system requires the Gen 4 4600 CommandCenter or 4640 Universal Display. These displays allow the operator to benefit from the updated interface, enhanced processing speeds, and easy setup (learn more in the Gen 4 CommandCenter feature).

SeedStar 3 HP conversion to SeedStar 4HP with mobile row-unit runoff aftermarket for field conversion kits

Growers who are currently running model year 2017 planters, model year 2017 and newer Precision Upgrades, or model year 2017 and newer custom-built planters with the SeedStar 3 HP monitoring system can upgrade to the SeedStar 4HP monitoring system with mobile row-unit runoff. The attachment part, AA100382, is software only. The Gen 4 display software version will need to be 19-1 or newer and will require planter apps. Follow the mobile runoff ordering and software push guide below for ordering and installation. Retrofitted planters and custom-built planters will also require the John Deere Connect Mobile kit, 0048PC, from the Precision Ag Technology Price Pages and wiring harness AA83662 to enable the mobile row-unit runoff feature. Please reference Parts Advisor and DTAC Solution 105181 for model-specific mounting brackets. SeedStar 4HP requires the Gen 4 4600 CommandCenter v2 display or 4640 Universal Display.

Default planter run pages

Planter summary default run page

Planter summary default run page

Planter overview default run page

Planter overview default run page

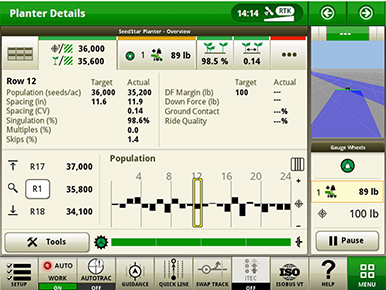

Planter details default run page

Planter details default run page

Three default run pages show key planter functions in different views to give fast and easy access to important planter information.

Custom run pages

Customizable run pages

Customizable run pages

There are customizable run pages that allow the operator to build pages that fit their operation with different modules, like the example shown above.

Zoom functionality

Zoom feature showing a group of rows

Zoom feature showing a group of rows

Zoom feature showing a single row

Zoom feature showing a single row

The zoom feature allows the operator to touch a section or row of the planter and get detailed information quickly.

Dual bar graphs

Dual bar graph showing singulation and population simultaneously

Dual bar graph showing singulation and population simultaneously

Dual bar graphs allow operators to view multiple planter details at one time.

SeedStar application page

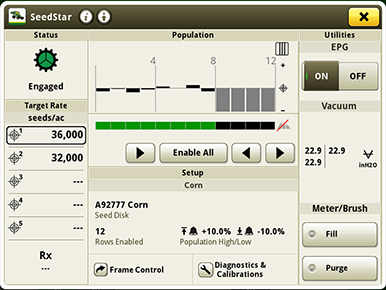

SeedStar application run page

SeedStar application run page

In the SeedStar application, many adjustments can be made, including manually activating section control. SeedStar 4HP allows up to 48 individual row sections. There are several setup features such as crop, seed disk, number of rows being planted, population alarms, and limits. Seed rates can be modified, electric power generation (EPG) can be turned on or off, vacuum can be adjusted, and the fill and purge functions can be used from the SeedStar application. Frame control, as well as diagnostics and calibrations, can be accessed at the bottom of the screen.

Settings Manager in SeedStar 4HP

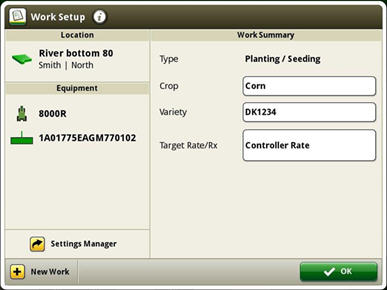

Access Settings Manager on the Work Setup screen

Access Settings Manager on the Work Setup screen

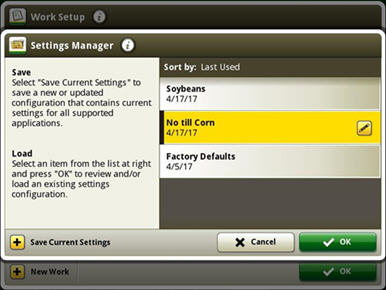

Settings Manager screen

Settings Manager screen

Reduce set-up time between changing crops or field conditions by recalling saved settings used previously with Settings Manager, included with every SeedStar 4HP system. This feature allows saving and recalling planter and tractor settings for optimum performance in different conditions.

Settings Manager can be used to save all the adjustment and inputs associated to a particular crop or condition. An example would be to store all population rates, downforce pressure, row cleaner adjustments, and closing wheel settings for planting corn and storing a separate, unique set of adjustments for soybeans. In addition, Settings Manager stores tractor settings such as selective control valve (SCV) flow and detents, infinitely variable transmission (IVT™) settings, eco modes, and more.

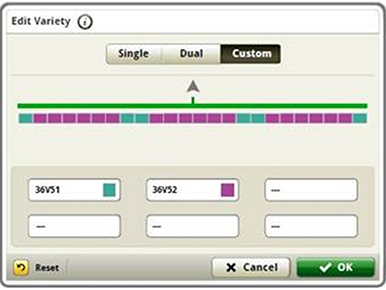

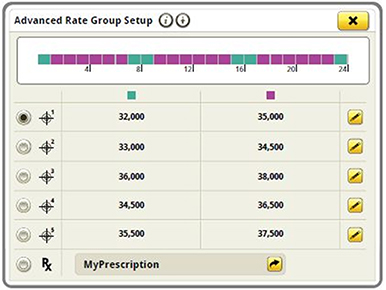

Custom rates in SeedStar 4HP

Variety set-up page

Variety set-up page

Rate set-up page

Rate set-up page

Group rate set-up page

Group rate set-up page

Custom rates allow for individual row population control and row-by-row documentation where up to six different rates can be assigned across an up to 48-row planter. This allows growers interested in planting seed corn with ExactEmerge or MaxEmerge 5e the capability to assign specific populations to male and female rows for planting. This feature can also be used to create tram lines or other applications where custom rates by row are needed.

NOTE: Individual rates are tied to varieties, so each individual rate needs a unique variety name.

NOTE: Advanced rates are not compatible with prescriptions or they cannot be run at the same time.

Additional information

For additional information on feature functionality on the Gen 4 Display, visit the links below:

YouTube is a trademark of Google LLC.

Compatibility

| SeedStar 4HP compatibility | |

| Planters | All models ordered with ExactEmerge or MaxEmerge 5e row-units NOTE: Precision Upgrades are equipped with SeedStar 3HP only but can be upgraded by purchasing part number AA100382. |

| Displays | Gen 4 4600 CommandCenter equipped with Version 2 Processor or 4640 Universal Display Dual-display mode is compatible with mid model year 2019 planter software. |

| John Deere Active Implement Guidance™ | Compatible with SeedStar 4HP on Gen 4 displays with VT mode and required activations and subscriptions |

| AutoTrac™ Implement Guidance | SeedStar 4HP is compatible with AutoTrac Turn Automation and AutoTrac Implement Guidance; not compatible with greater than 48 row electric drive planters. |

| AutoTrac Turn Automation | SeedStar 4HP is compatible with AutoTrac Turn Automation and AutoTrac Implement Guidance; not compatible with greater than 48 row electric drive planters. |

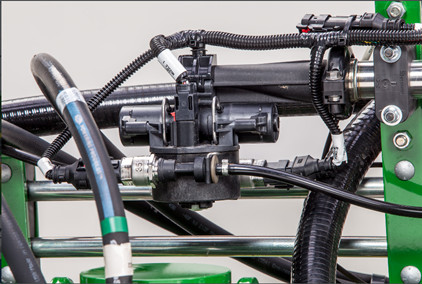

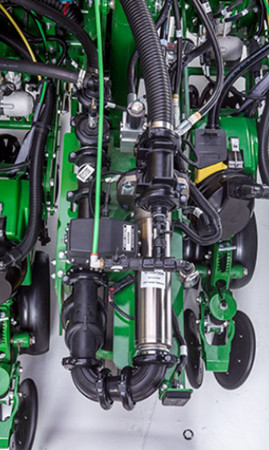

ExactRate pump assembly at rear of 12-row 1775NT

ExactRate pump assembly at rear of 12-row 1775NT

The ExactRate liquid fertilizer system is a factory-installed solution that provides you with accurate nutrient placement during planting. Previously, you would have to deal with the inconvenience of cumbersome aftermarket systems for a hydraulically driven variable-rate solution. With ExactRate, John Deere delivers a complete planting solution for liquid fertilizer users. You can choose between in-furrow or offset delivery methods. A high-rate option without openers is also offered from the factory. This system delivers:

- Up to 20 percent more accurate nutrient placement in a turn compared to a non-turn compensating system

- 1 to 12 percent (4.3 percent on average) reduction in inputs through row-by-row section control

- Ability to run up to 16.1 km/h (10 mph)

- Closed-loop speed and rate change compensation

- Full integration into the 4600 CommandCenter™ and 4640 Universal Display

ExactRate nozzle body

ExactRate nozzle body

The ExactRate liquid fertilizer system is designed to take full advantage of the capabilities of ExactEmerge™ and MaxEmerge™ 5e planters. This factory-installed liquid fertilizer system delivers the same value as your electric drive planter including working at speeds faster than the traditional 8.05 km/h (5 mph), turn compensation, and row-by-row section control, all while accurately compensating for varying rates and speed changes. Additional features include row-by-row flow detection, as-applied documentation, and variable-rate capabilities, providing operators full integration into the 4600 CommandCenter or 4640 Universal Display.

Fertilizer flows from the tank to the pump, through a strainer and boom isolation valve, through a central flowmeter, and out to each nozzle body and row-unit for accurate delivery. The system is closed loop, meaning the pump and nozzle body duty cycle both adjust based on feedback received from the pressure sensor and central flowmeter. This design helps maintain an accurate application rate.

NOTE: ExactRate is not recommended for products that require agitation to maintain suspension.

Pump

Pump assembly at rear of planter

Pump assembly at rear of planter

Instead of a tire-contact drive, a hydraulically driven centrifugal pump eliminates chain and sprocket adjustments to provide more speed flexibility over the entire rate range. This pump allows for a wide range of rate capabilities as well as strong durability. The wet seal design helps protect the pump if it is accidentally run dry for a short time.

Strainer

A strainer helps collect suspended particles and prevent them from causing blockages in the distribution system and nozzle bodies.

Boom isolation valve

The valve prevents the tank from draining out if there is a leak in the distribution system. If the pump is on, the valve opens to allow flow. When the pump is off, the valve closes.

Central flowmeter and pump pressure sensor

The central flowmeter and pump pressure sensor provide the rate control system feedback on flow and pressure to ensure an accurate application rate across the entire planter width. The flowmeter also supplies the as-applied rate data.

Direct injection

The ExactRate liquid fertilizer system does not have direct injection capabilities on the product being applied. If direct injection is needed on the secondary product, an additional rate controller is required.

NOTE: ExactRate system and John Deere Rate Controller 2000 with Raven ICD Direct Injection system is supported. ExactRate system and GreenStar Rate Controller with Raven ISO Direct Injection system is not supported.

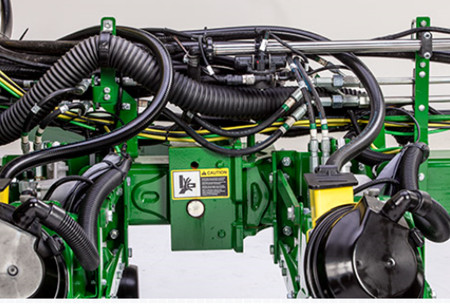

Distribution system and nozzle body

Distribution system and nozzle bodies routed on the wing of a 12-row 1775NT

Distribution system and nozzle bodies routed on the wing of a 12-row 1775NT

The 2.5-cm (1-in.) stainless-steel distribution lines not only reduce corrosion, but they also provide a clean integrated look. The distribution system is pressure tested at the factory to reduce the risk of leaks.

John Deere has leveraged ExactApply™ technology and capabilities from the sprayers to enable row-by-row section control and turn compensation that matches the high-performance planters. With ExactRate, there are no orifice changes for rate or speed adjustments, saving you time and effort while limiting exposure to product. Pulse-width modulation technology varies duty cycle (opening and closing of the valve) in the nozzle bodies in conjunction with flow and pressure measured from central flowmeter and pressure sensor controlling the system pump. The ExactRate liquid fertilizer system uses one nozzle body for two rows, limiting the number of parts and complexity on each machine. While you’re in the cab, you can keep an eye on each row with flow detection integrated into the Gen 4 display. The system warns you if it detects a variance in an individual row’s flow. A pressure sensor integrated into the nozzle body will detect a flow reduction or overapplication on the row.

Keypad at rear of planter

Keypad at rear of planter

Just like on the sprayers, the keypad at the rear of the machine lets you conveniently perform a nozzle flow check to ensure product is coming out of each row before going to the field.

Rate Controller

The ExactRate liquid fertilizer system is compatible with the John Deere Rate Controller 2000 and GreenStar™ Rate Controller if a producer wants to apply a second product using a separate distribution system.

ExactRate app on Gen 4

Easily adjust target rate and speed without leaving your seat. With turn compensation, inner and outer rates are automatically adjusted to maintain consistent application across the full width of the planter. This ultimately reduces the risk of seed burn by over application (turn compensations require a global positioning system [GPS] receiver). Another helpful feature is row-by-row section control for reduced overlap on headlands and waterways. Gen 4 Documentation creates as-applied maps showing what product was applied where, providing accurate record-keeping.